SOUND INSULATING PANELS

∼

SOUND ABSORBING PANELS

- sound insulating panels: prevent the spread of noise outside by reflecting the sound in the environment from which they come

- sound absorbing panels: completely absorb the sound energy

Generally, to ensure good room acoustics, it is useful to think of sound insulation as a system: Sound-absorbing materials are mainly used to improve the acoustic quality in interiors while sound-insulating materials are used to protect against external noise.

Sound Insulating Panels

The soundproofing of environments plays a fundamental role in working, living and recreational comfort especially in urban contexts often characterized by a high level of noise both outside and inside the buildings.

La migliore insonorizzazione è garantita dal rispetto di una serie di parametri che le nostre soluzioni assicurano al 100%.

High quality soundproofing panels are those with a high specific weight, such as rubber, lead, steel, solid wood, glass or marble usually supplied in the form of sheets that are easy to transport and install.

Today heavier materials - such as lead - tend to be replaced by more manageable, newer solutions, while maintaining optimal acoustic properties.

Generally, three categories of soundproofing panels are identified, each with specific characteristics and areas of use:

- Natural Soundproofing - made from the resin of the barks of certain plants

- Artificial Soundproofing - based on building materials (glass wool, plasterboard, etc)

- Synthetic Soundproofing - polymer-based

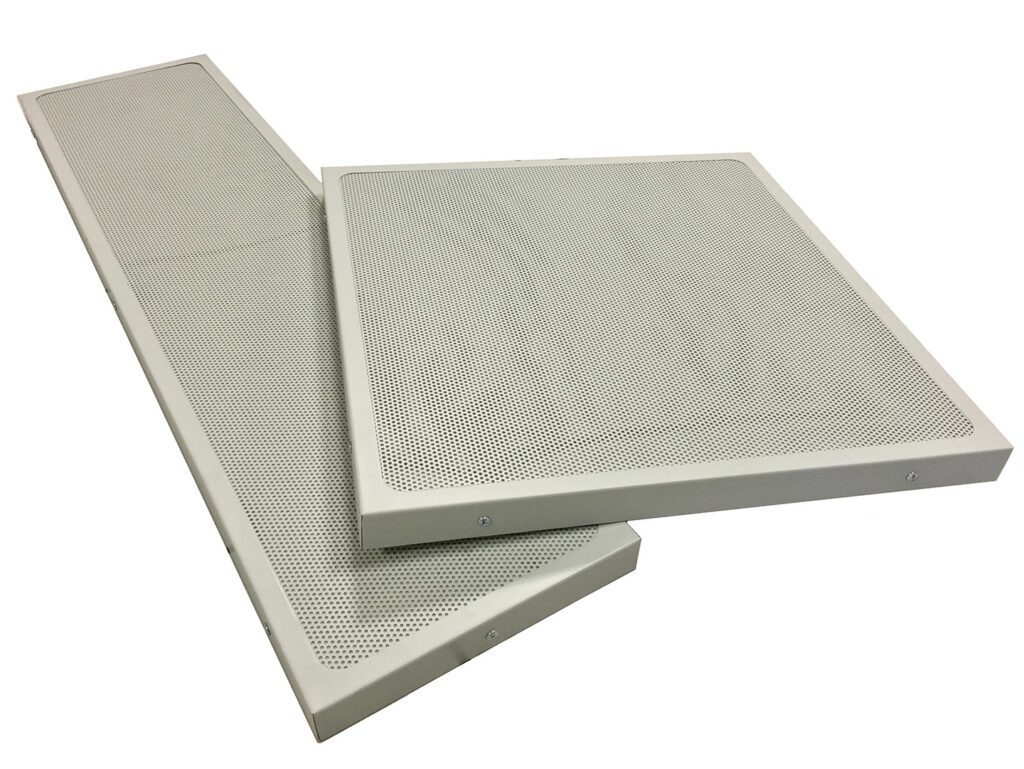

Sound Absorbing Panels

Sound-absorbing panels have the function of limiting reverberation within confined spaces.

Used to correct the characteristics of the sound wave in terms of reverberation, sound-absorbing panels meet the soundproofing needs of machinery and premises to ensure noise control.

Sound-absorbing panels are usually materials with spongy consistency or otherwise low density or compact materials (wood,

metal, plastic materials, etc.

Sound absorbing panels can also have worked and colored surfaces and can be covered with fabric, associating to the prevailing function of "acoustic correction" also a value of aesthetics and design.

The panels can be installed on walls and/or ceilings with specific conformations for each environment and need. They can also be installed continuously or in groups and made fixed or mobile thanks to the use of adhesives or hooks and brackets.

The absorption capacity of the panels is regulated by the standard UNI EN ISO 11654 which classifies them according to the weighted sound absorption coefficient represented by a value between 0 (no absorption) and 1 (absolute absorption):

The classes are:

- Class A - coefficient between 0.90 and 1

- Class B - coefficient between 0.80 and 0.90

- Class C - coefficient between 0.60 and 0.80

- Class D - coefficient between 0.30 and 0.60

- Class E - coefficient between 0.15 and 0.30

- Not classified - no absorbency (soundproofing materials)